Laser induced Defect TiO2 for Solar Panels and Water Sensing

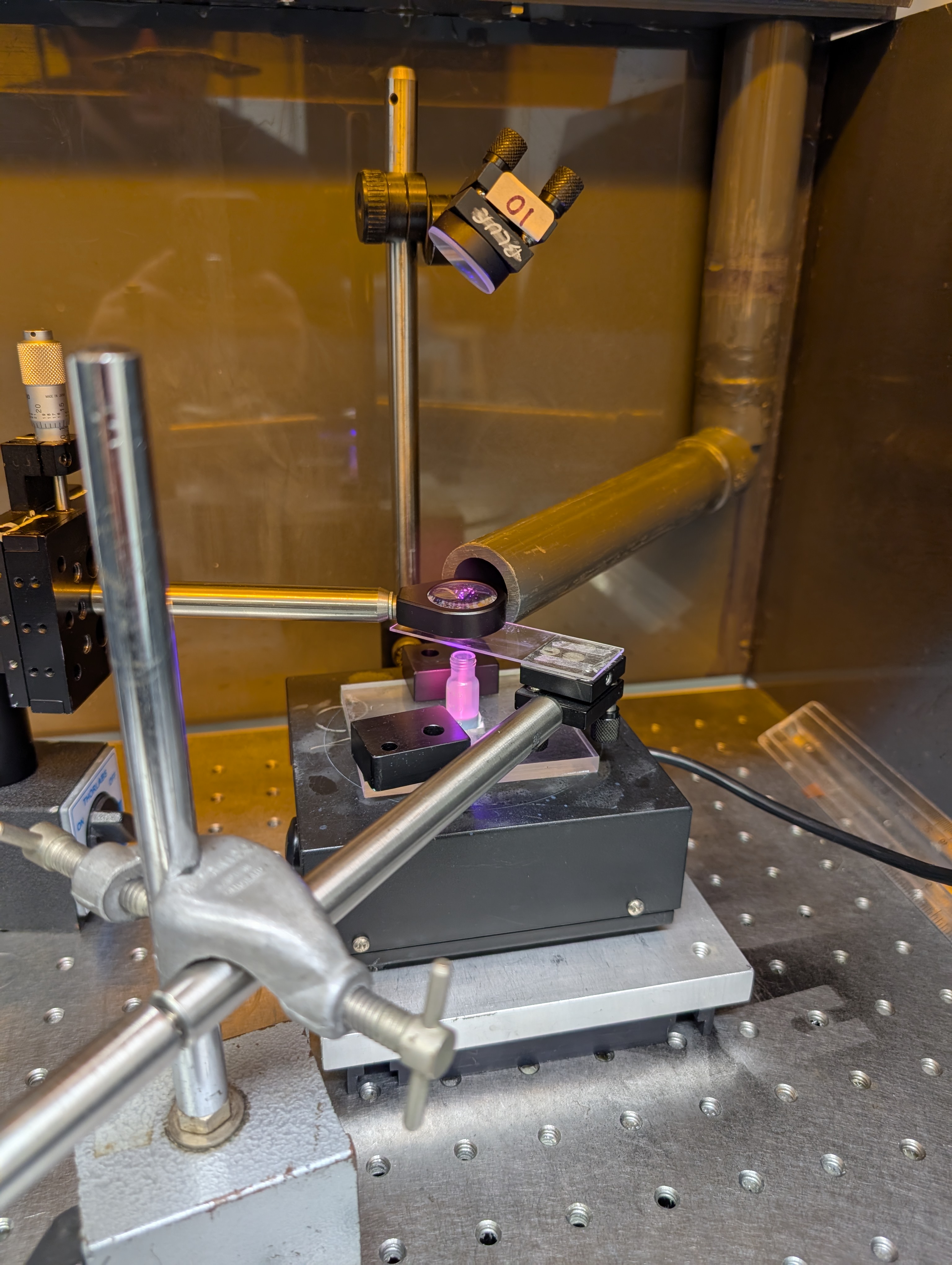

Femtosecond Laser Setup

Photoanode degradation >:(

Project Overview

My role focused on developing laser-induced defect TiO₂ photoanodes for applications in solar energy conversion, organic pollutant oxidation (breaking down harmful chemicals), and wastewater sensing. Key objectives included achieving uniform defect engineering, preventing photoanode degradation, and ensuring reliable fabrication for industrial adoption. Using root cause analysis with cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS), I identified and mitigated degradation mechanisms in TiO₂, enabling stable performance. I optimized spray-coating deposition parameters (e.g., material composition, pressure, and surface treatment) to control film quality, nanosecond-pulsed TiO₂ for Ti³⁺/oxygen vacancies, and femtosecond-pulsed TiO₂ for surface-localized Ti³⁺/oxygen vacancies. Batch-to-batch variability was addressed through Python-driven data analysis, which correlated process inputs with material properties. Standardized protocols were then developed to ensure reproducibility across academic and industrial settings.

Technologies Used

- Electrochemical methods: CV, LSV, EIS, for redox couples, (ir)reversible capacitive effects, double layer charging, approximate electrochemical surface area, and solar light

- Nanosecond/femtosecond pulsed lasers to tailor TiO₂ defect profiles

- Spray coating, optimized for 95% throughput with controlled porosity/thickness

- Data acquisition with BioLogic and analysis with Python for quality analysis and control

- Material characterization with SEM, and XRD (not by me) to validate defect states (Ti³⁺, oxygen vacancies), UV-vis for pollutant oxidation behavior

Results

- Eliminated photoanode degradation, enabling the material to be photocatalytically tested

- Achieved 95% throughput in electrode fabrication via spray-coating optimization

- Reduced batch variability by 70%, process design validated for small scale

- Soon to be published :D