Deposition Process Design

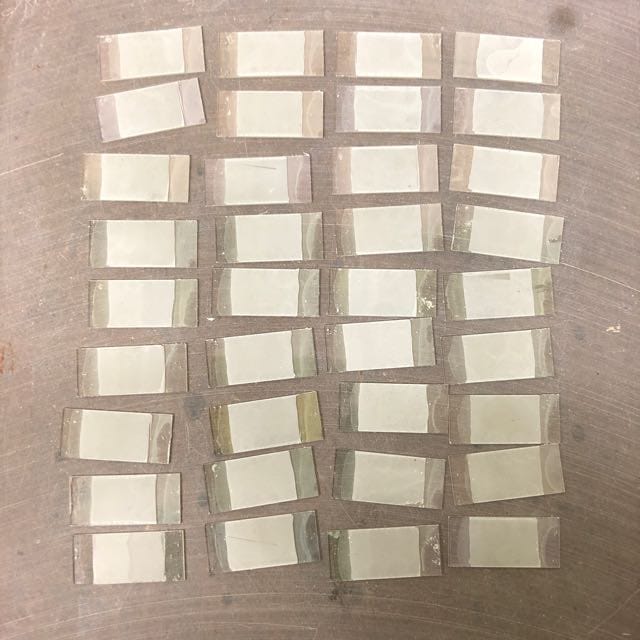

Before Implementation

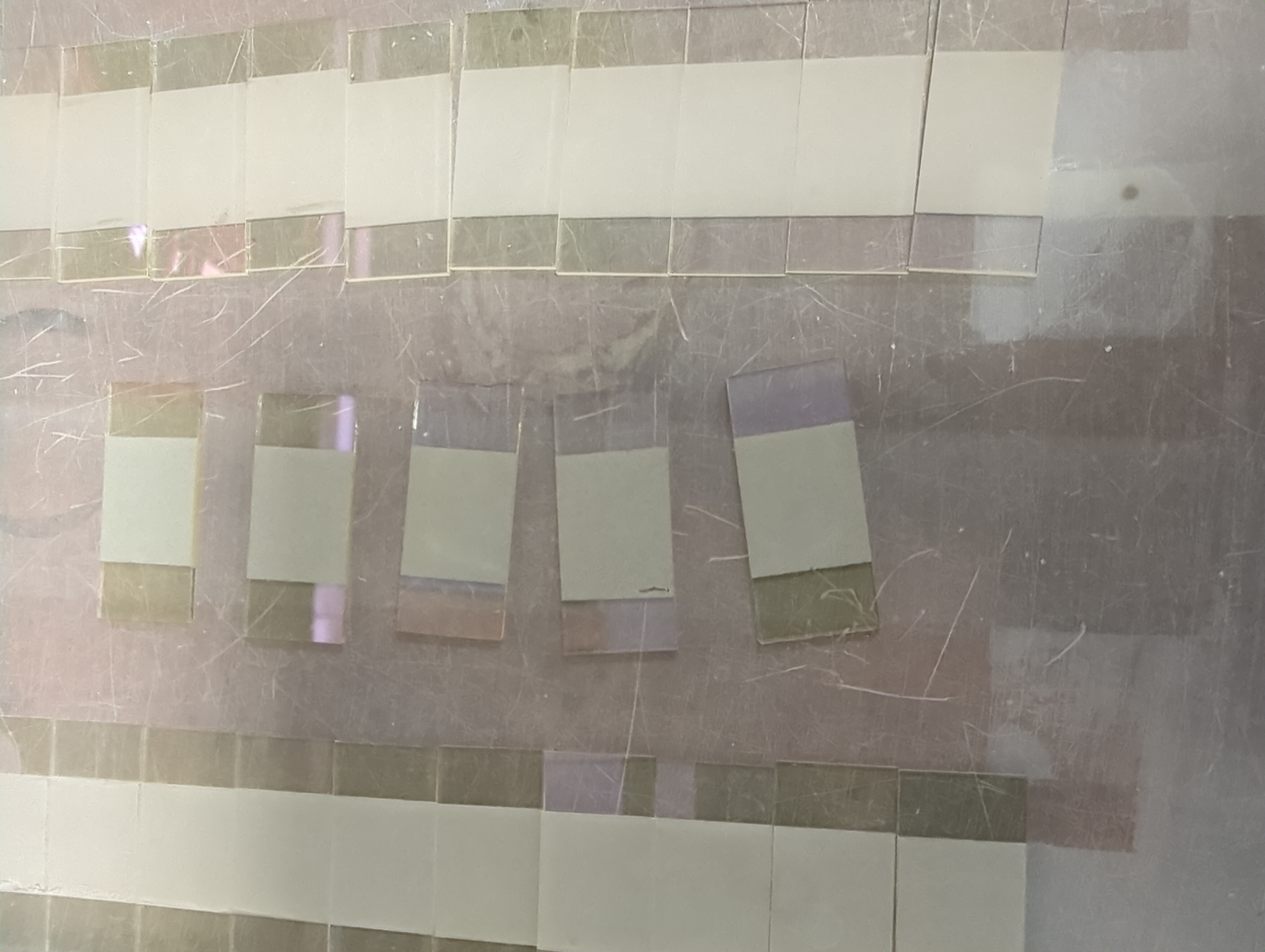

After Implementation

Project Overview

My role was to develop a deposition process for MANTECH’s chemical oxygen demand (COD) biosensors. I wanted to achieve a uniform coating of the photoanode material on the substrate, increase yield, and improve adhesion (therby lifetime of the sensor). My two main focuses were on the environmental factors affecting the deposition process (temperature, humidity) as well as the human error/variability observed bewtween batches. I tuned the solution's surface tension to ensure it could be evenly deposited onto the substrate with the desired thickness and porosity. The initial results were promising but indicated room for improvement in yield and adhesion. To enhance the yield, I adjusted deposition parameters and implemented new quality assurance (QA) steps using data acquisition. The adhesion issues between batches were solved by employing a surface treatment normally used for silicon wafers in the Quantum Nano Fabrication and Characterization Facility (QNFCF) cleanroom. I then created comprehensive standard operating procedures (SOPs) and instructional videos to ensure the process could be consistently replicated for device production.

**I signed an NDA with MANTECH and am unable to share the exact details of the deposition process.**

Technologies Used

- UV-VIS spectroscopy to monitor oxidation of reference pollutants

- Plasma etching to clean and functionalize the surface for wetability (in cleanroom)

- Open source process flow tools to design, test, and ensure QA standards are met

- Python for data aquisition, analysis and process optimization

Results

- Quality assurance (QA) protocols, allowed a 150% increase in device production volume

- Device yield was increased by 15%, manufacturing time reduced by 40%

- Environmental factors no longer have drastic (or any observed) affects on yield

- MANTECH’s in-house average QA runtime was reduced from 6h to 3h due to the film's stable nature