Nano Silver Conductive Inks

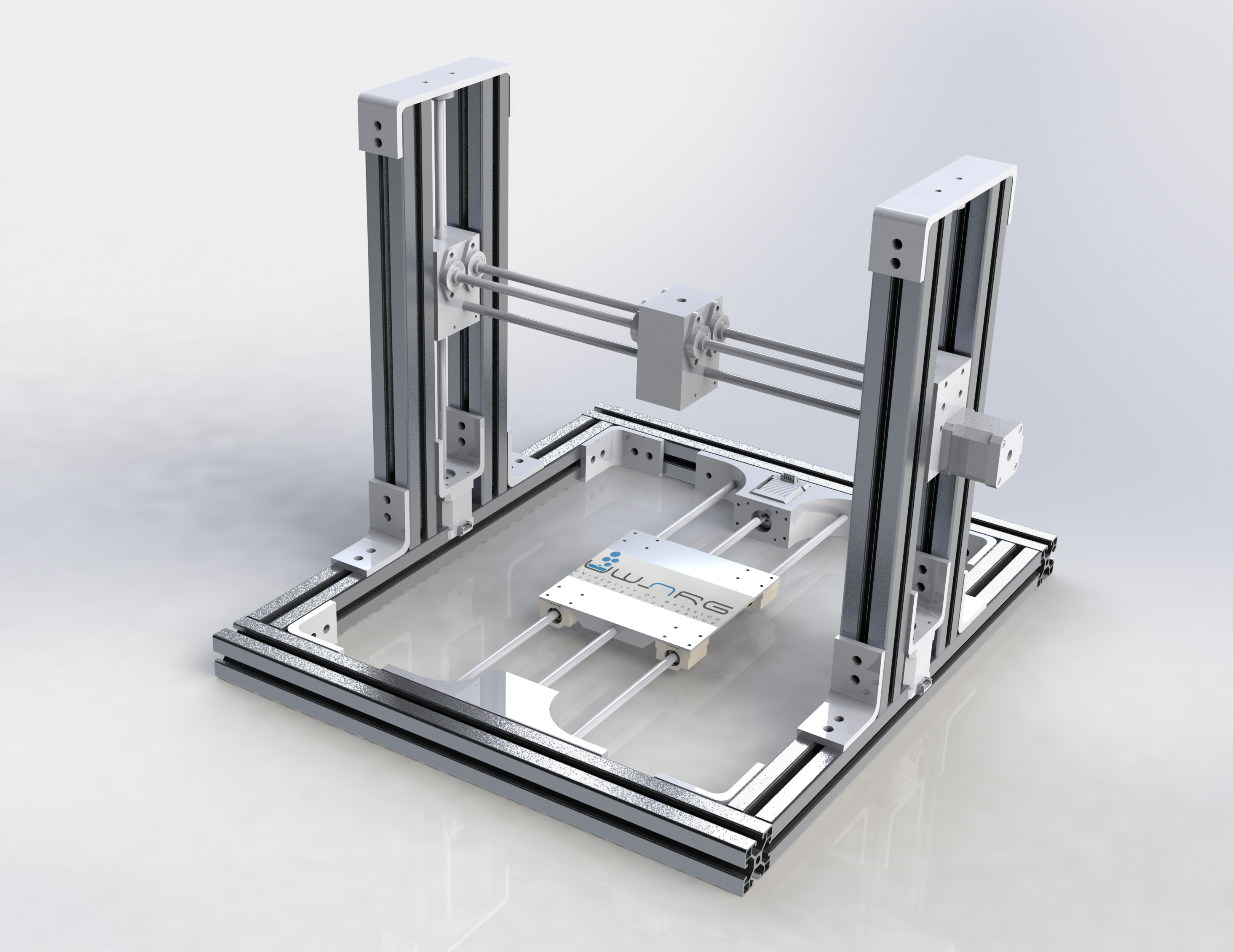

Conductive Hybrid Ink Printer (CHIP)

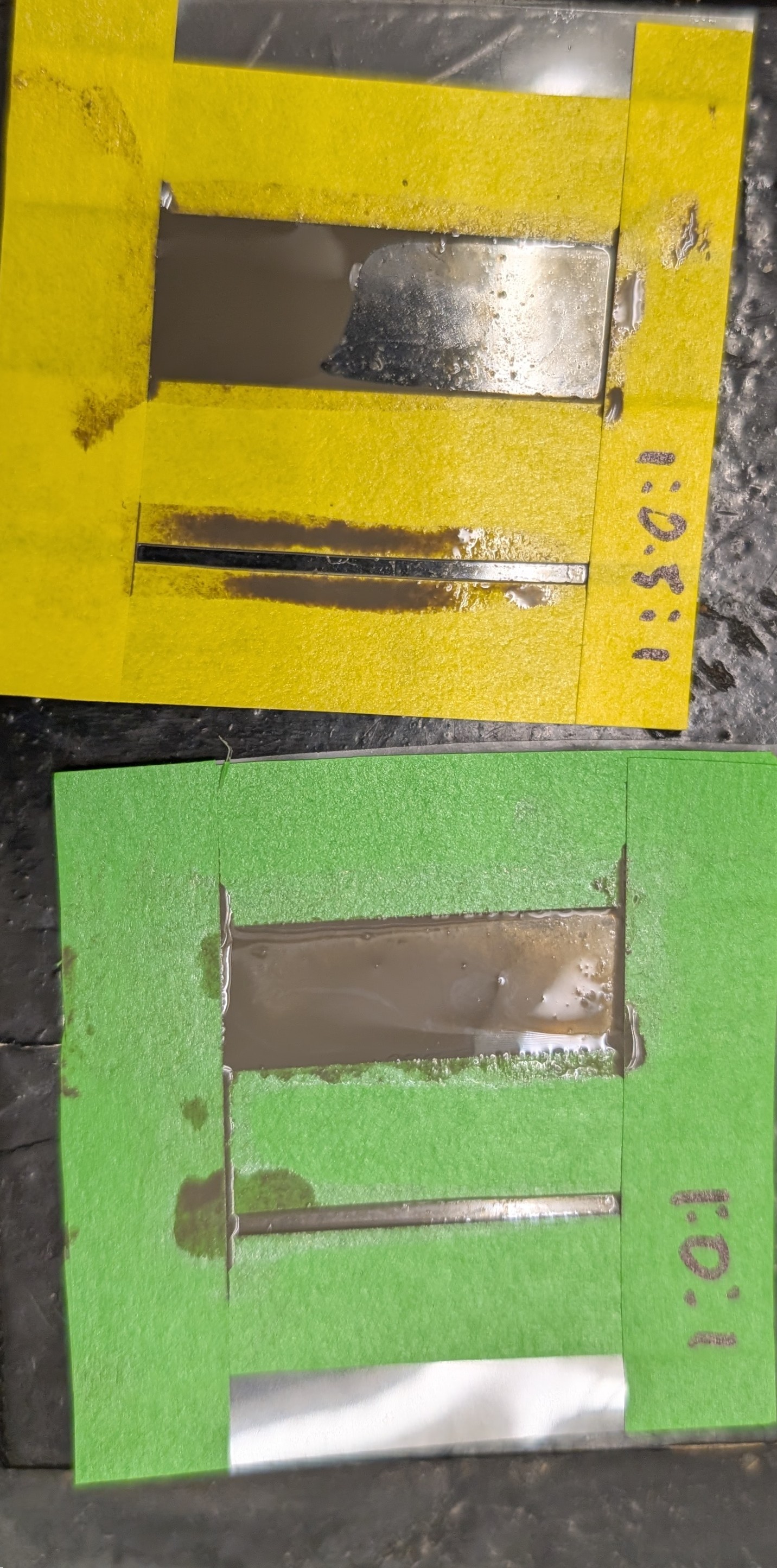

Tested Viscosity Across Different Solvent Ratios

Project Overview

In this project, I led a multidisciplinary team focused on the synthesis and optimization of conductive inks for additive manufacturing, specifically targeting silver nanoparticle formulations for flexible PCBs in wearable electronics. This ink could be used by the printer the mechanical team was designing (CHIP, pictured above). My leadership responsibilities included setting project milestones, aligning team goals, and facilitating R&D, production, and quality assurance (QA). I established clear communication channels and coordinated the creation of technical documentation such as SOPs and BOMs to ensure knowledge transfer and process consistency. By mentoring junior researchers and fostering a collaborative lab environment, I helped drive innovation in ink formulation, deposition techniques, and performance testing, all while maintaining a strong focus on safety and reproducibility.

Technologies Used

- SEM/XRD/DLS for nanoparticle morphology, crystalline structure, and size distribution, respectively.

- Collaborative tools (Git, Notion) for version control and technical documentation

- Python scripts for analyzing conductivity/adhesion test data

- General lab skills and knowledge transfer

- Thermal sintering ovens with programmable temperature profiles

Working On

- Conductivity improvements -> mainly particles diameter control and mass loading

- Viscosity control -> Optimizing binder-to-solvent ratios for printhead compatibility

- Sintering processes -> Literature review and emperical testing